Technical Advantages of PFA (Perfluoroalkoxy) Coatings in High-Performance Industrial Applications

Exceptional Non-Adhesive Interface:

Exceptional Non-Adhesive Interface:

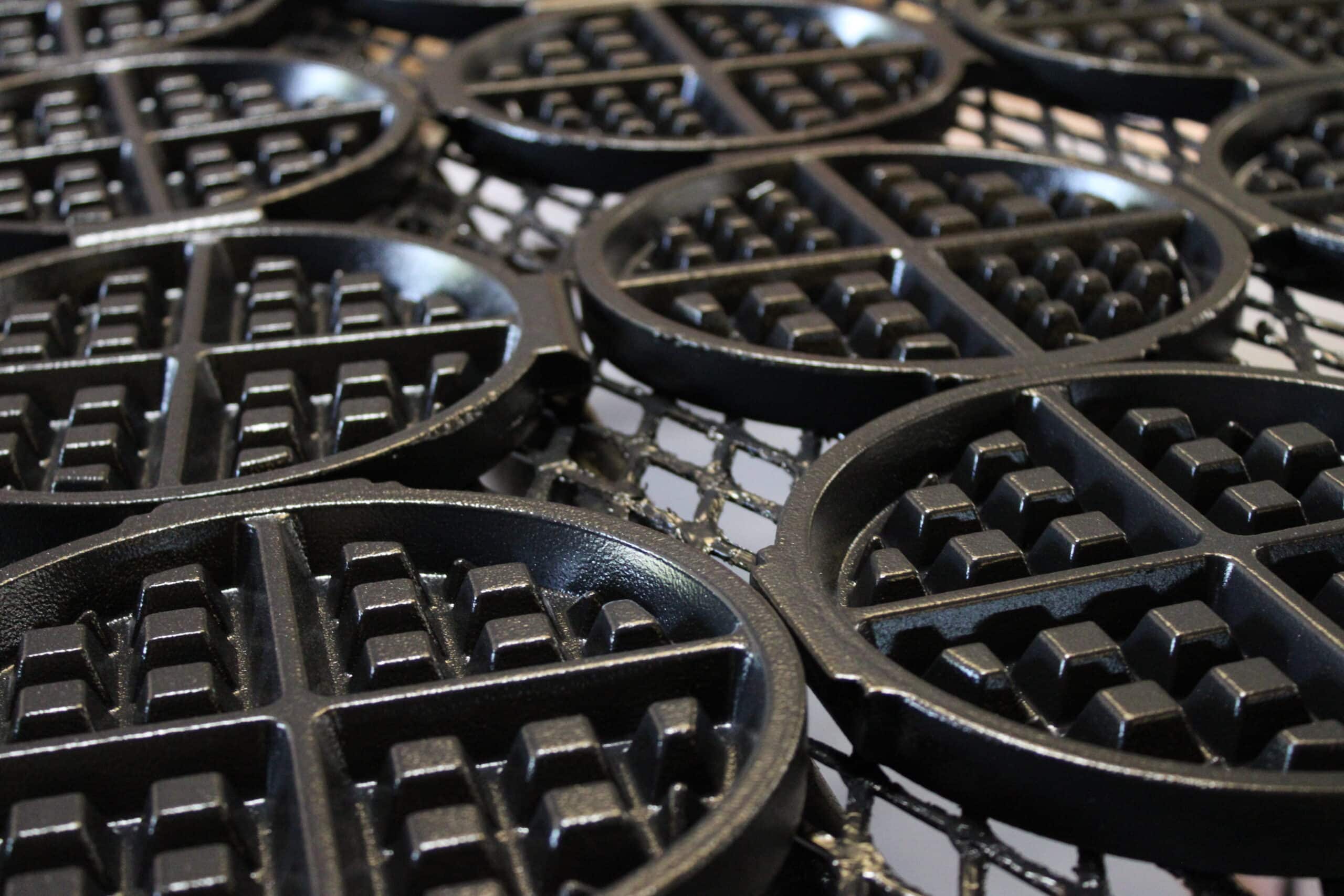

Characterized by an ultra-low surface energy and minimal interfacial tension, PFA coatings significantly inhibit substrate–material interactions. This property prevents the adsorption and accumulation of polymers, food residues, and pharmaceutical compounds on tooling surfaces (e.g., molds, extrusion dies), minimizing process interruptions, reducing manual cleaning intervals, and mitigating product contamination risks.- Robust Thermal Stability:

Engineered to sustain continuous operation at temperatures approaching 260°C, PFA coatings preserve their morphological and crystallographic integrity under severe thermal cycling. As a result, they maintain consistent tensile strength, elongation at break, and chemical inertness in high-temperature process equipment such as heat exchangers, polymerization reactors, and high-temperature molding assemblies, thereby enhancing operational reliability. - Comprehensive Chemical Inertness:

The perfluorinated backbone structure of PFA exhibits negligible reactivity with a broad spectrum of aggressive media, including strong acids, bases, oxidizers, and organic solvents. This near-universal chemical resistance prevents corrosion of substrates—such as reactor linings, transfer piping, and containment vessels—preserving dimensional stability, preventing leaching or cross-contamination, and extending equipment service life under harsh chemical regimes. - Elevated Mechanical Durability and Flexibility:

Relative to conventional fluoropolymers, PFA coatings display improved toughness, impact resistance, and elastic recovery. Their reduced propensity for microcracking under mechanical stress and vibrational load makes them suitable for applications involving dynamic pressure fluctuations, abrasive particulates, or mechanical agitation. This mechanical resilience yields a longer operational lifespan and lower replacement rates for coated components. - Strict Regulatory Conformity and Process Purity:

Complying with rigorous standards such as FDA, USP Class VI, and semiconductor-grade specifications, PFA coatings facilitate stringent contamination control and high-purity processing. Their inert surfaces prevent adsorption of impurities and microbial proliferation, ensuring that food, pharmaceutical intermediates, and semiconductor wafers remain uncontaminated. The coatings’ compatibility with CIP (Clean-In-Place) and SIP (Steam-In-Place) protocols further supports sanitary operations and simplified maintenance.